Needle with his hands - detailed instructions for making, tips, photo examples

Needlepoint is a very useful and useful thing. Unfortunately now a good awl is not found, no one even thinks to do something with their own hands, because there are specialized shops.

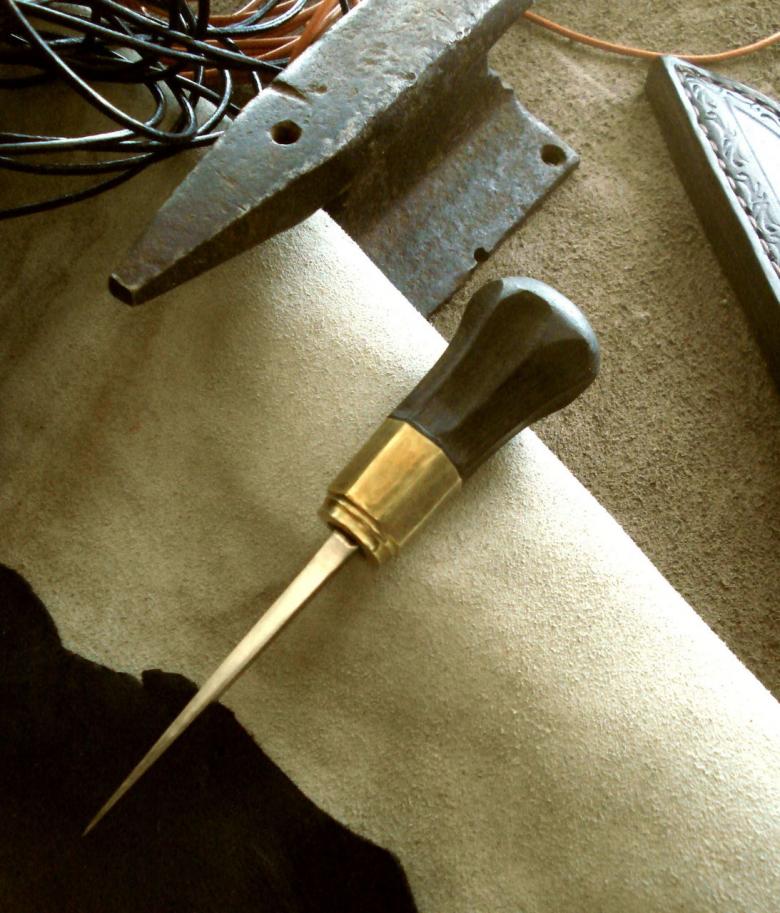

And the need for awl, contrary to constantly developing and available workshops, can always arise. For example, there is a need to punch another hole in a leather belt, and at the same time to do it beautifully and neatly, so as not to spoil the appearance of the belt.

It so happens that people do not feel an acute need for this tool, and stores, due to lack of demand, do not have it on the shelves. In this article, we will look at how to make an awl with your own hands.

Types

Before proceeding to the manufacture, you need to decide what kind you need. Let's consider what kinds of awls there are, and what they are needed for.

- Normal, straight. The most common, very common and easy to make.

- Hook. It is used for the purpose of pulling the thread through the hole.

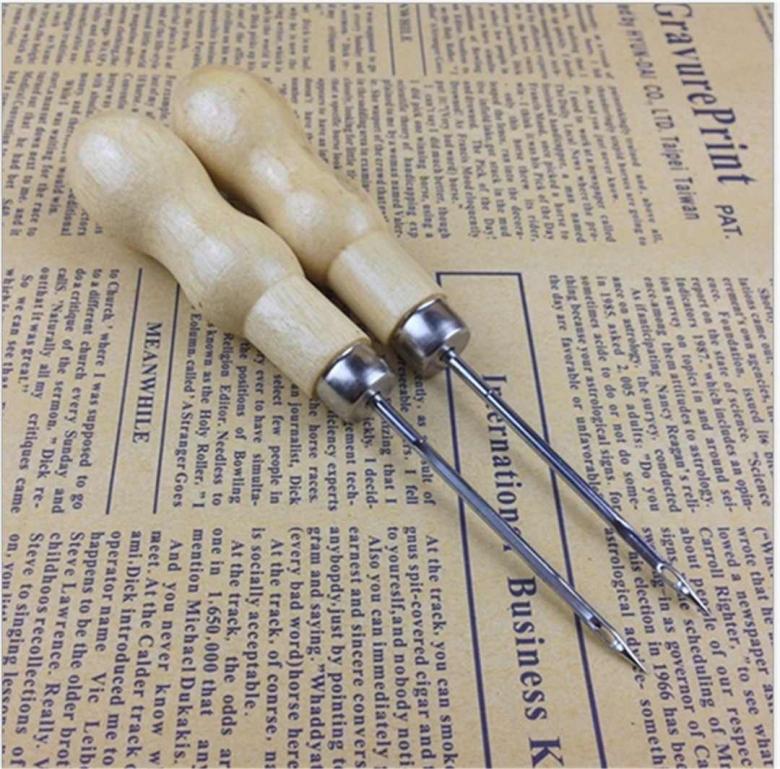

- With an eyelet. Made in the manner of a sewing needle, but found only in sewing shops. Used for the purpose of sewing thick material.

According to its size, the awl can be absolutely any, it depends only on the requirements of the master to the tool, and the nature of the upcoming works.

Materials

In order to make such a tool with your own hands, you will need a number of materials and some tools.

For the basis, it is easiest to take a long self-tapping screw. This is a very popular solution, but thick material is not punctured by such, as it simply will not work on a self-tapping screw. You can, of course, grind it down, but it's long and pointless.

Another option is a long nail, but it is softer than a self-tapping screw. This means that it will need to be sharpened much more often to keep it sharp.

Making Methods

The technique for making the awl itself is very simple, in fact in 2-3 points. However, depending on what tasks the tool is needed for, it may differ somewhat. If it will be needed only to punch new holes in belts, you can not even think much about the handle.

It is quite possible to take a long steel rod, bend or twist one part slightly, and sharpen the other. If the tool is required for more serious work, you need to take care of a reliable handle.

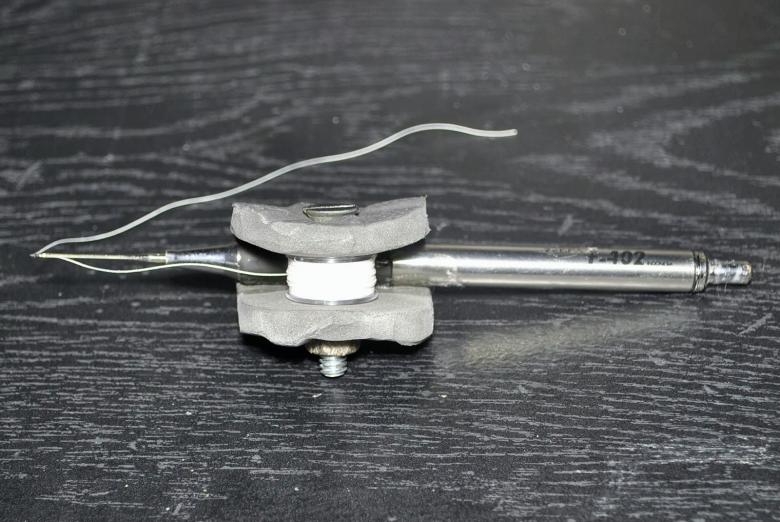

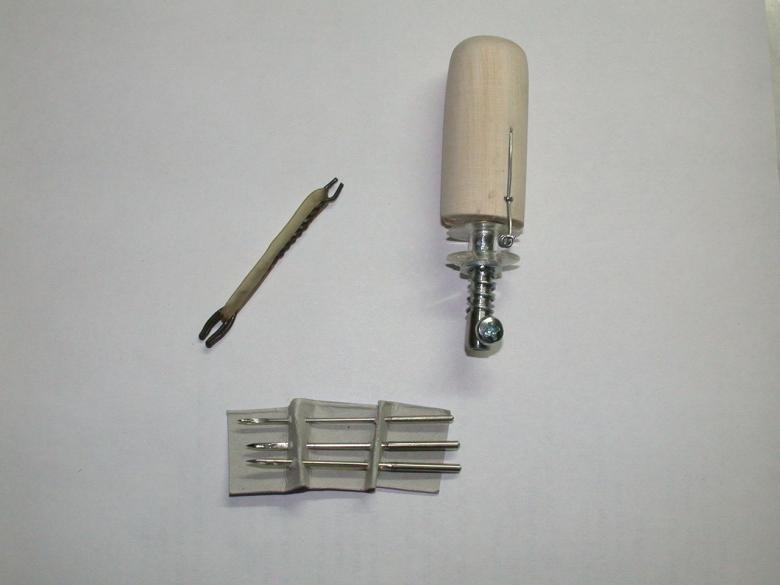

It is also possible to make a whole body in the handle. This is done in order to be able to change the awl itself, depending on the task. It is very convenient and compact.

The easiest and most reliable way

With the main types of tools and their purpose we have understood. There is no point in enumerating all the existing methods of manufacture, there is a huge variety, it all depends only on the imagination of the master.

Here is the simplest, and at the same time the most reliable way. For this method, we will need an ordinary long self-tapping screw made of good steel, so that it does not bend. We will use a wooden bar as a handle. Its width should be equal to the width of the palm, so that it was convenient to hold.

The least popular option is steel wire, it is hard enough and very easy to sharpen. Literally anything can be used as a handle. The main thing is that it must be firm and the awl itself must sit very firmly in it. Otherwise, it can slip out of the socket and injure the craftsman.

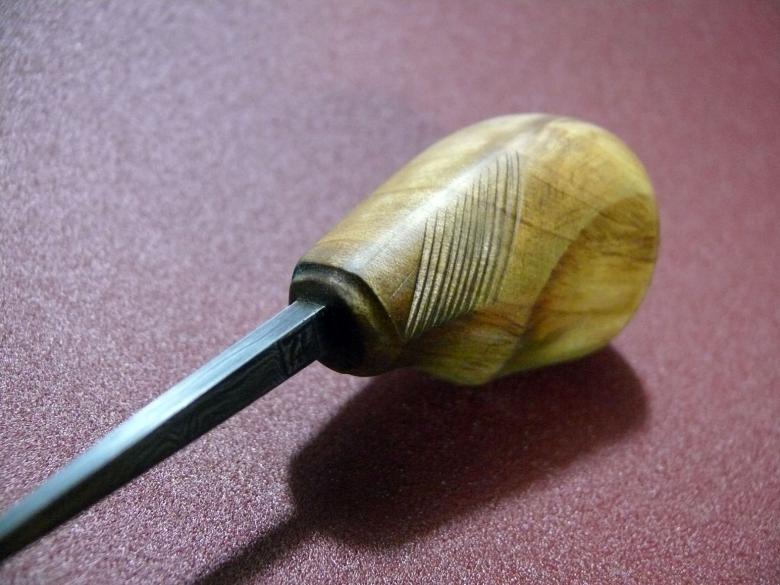

The wooden bar should be first qualitatively ground to the size of the hand and then machined, so as not to plant itself a splinter. Next, you can make the handle unique by carving a pattern on it, or you can burn your initials.

The next step is to drill a hole in the handle directly for the awl. Note that the diameter of the hole should be the same as the diameter of the screw. If it is larger, the awl simply will not hold.

Screw the awl into the drilled hole, it should sit tightly and not move. Then we cut off its head. The final step is sanding. In order not to reduce the strength characteristics, it is necessary not to grind the edges strongly, and the tip to do with the edges, about 3-4. After that, bring to perfection with sandpaper, and the awl will be ready.

You can use the tool immediately, having tried it out directly in the work. Next, consider how to make such a tool as a gift for someone.

Gift

The algorithm of actions is basically the same, but a number of additional ones are added. You can use the same self-tapping screw as the base. But the handle must be unique, beautiful. For this purpose it is necessary to choose quality wood, mahogany will look very beautiful.

It is possible to make a tool with removable attachments, for different types of work. To do this, you need a few circles, or squares, which will serve as an attachment. On the basis of the same handle, you can make a simple metal slide that will lock the nozzle.

A hole is drilled in each nozzle, where the nozzles are then screwed in. After that, they are grinded, brought to perfection. It is necessary to check each head for compatibility with the handle, they should not be freely inserted, but should not dangle as well.

Such a gift will be appreciated by the cobbler, who by the duty of his work constantly "communicates" with this tool. You can engrave his initials and wishes on the handle.

We've broken down several ways to make virtually any taste. The materials are available to everyone, can be found in any home. The process itself takes no more than 10 minutes, and the result will please its owner for a long time with the high-quality work done with it.

This is an original gift that will definitely make you stand out from other friends.