Cart with their own hands - popular design options, detailed master class, photo ideas

Garden wheelbarrow - one of the most necessary attributes on the dacha plot. With such a design, you can easily transport dry branches, leaves in the fall, loose materials (crushed stone, cement, soil) during construction works. You can buy a convenient and sturdy cart in any store of construction materials. However, using detailed instructions, you can make a garden wheelbarrow yourself with a minimal set of materials.

Types of garden wheelbarrows

Depending on the number of wheel pairs on the design, the following types of wheelbarrows are distinguished:

- Single-wheeled wheelbarrow. This design is less maneuverable and stable than two-wheeled models. The wheel is centered at the front of the cart, and a heavy handle and stop are used as a counterweight.

- A wheelbarrow with two wheels. The most common model. A symmetrical pair of wheels creates an additional stop, so this type of construction is particularly stable.

- Wheelbarrow with four wheels. Not too common a garden cart model. Two pairs of wheels create a maximum stop, allow you to work with heavy and oversized cargo.

A significant disadvantage of wheelbarrows with two and four wheels is the need to modify the garden paths. The axles of such wheelbarrows are much wider than a single-wheeled cart, so the width of the paths must also meet the requirements.

Step-by-step making of a cart

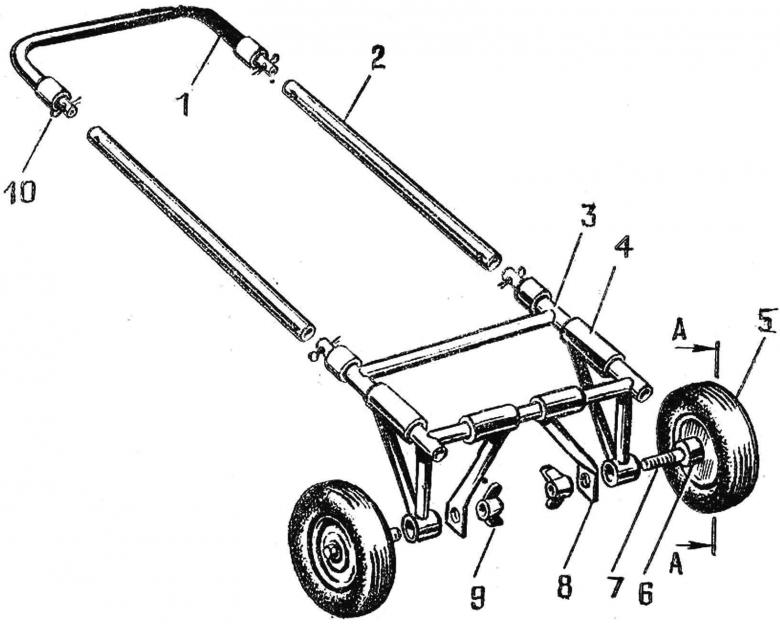

To make a garden cart at home, you need to prepare the following parts and tools:

- Basic material - plastic, wood, sheet iron.

- Fixing mechanisms.

- Wheel sets.

- Axles for wheel fixation.

- Auxiliary fittings: handle, construction guides, stop.

You should also have ready-made drawings, but the scheme of the device will depend on the chosen model. The entire process of construction work can be divided into several stages:

- Selection of dimensions and creation of a drawing.

- Arrangement of the frame installation.

- Installation of the running gear.

- Fixing the handle.

- The arrangement of the main body.

Each step is performed sequentially, and with reference to the scheme-instruction. As a master class, it is worth considering the instructions for creating a wooden cart for garden work.

Dimensions and drawing for a cart

From the size and shape of the cart depends on its stability in further use. Standard dimensions have a wheelbarrow with the following parameters:

- The cross-section should not exceed 60 cm.

- The maximum length of the frame unit is 100-110 cm.

- The height of the body is in the range 55-60 cm.

With compliance with all size requirements the garden wheelbarrow will be as stable as possible, even without taking into account the additional support.

Setting up the frame setup

Preliminary wooden workpieces are subjected to special treatment: impregnated with antipyretic, antiseptic and antifungal solutions. This step will significantly extend the life of the construction, increase resistance to moisture, protect against pests. The surfaces can also be further sanded with sandpaper. To mount the frame connect the bars at the joints, using screws and metal corners to further strengthen the installation.

If you intend to make a framework of metal pipes, you should use an angle grinder to cut parts and welding to connect the frame. Before further assembly, it is best to cover the product with water-based paint to prevent possible corrosion.

Mounting the undercarriage

The bearing rails are mounted on the underside of the future cart. The rail for one wheel is placed along the vertical axis, centering the weight.

For 2 or 4 wheels, parallel wooden strips are used, on which the hardware is mounted. You can also use a ready-made axle from an old cart. At the same stage, the wheels are attached and a trial rolling of the wheelbarrow is carried out to detect malfunctions.

Mounting the handle

According to the advice of experts, the handle should be made from a strong iron bar. Experts advise using a bicycle handlebar or a mount from an old scooter. In the technology of the fastening mechanism, the choice is left to the master: to make the handle fixed or folding on hinges.

Arrangement of the main body

The body is made of durable material with sufficient resistance to moisture and mechanical damage. Such material is most often metal sheet. For the work you will need to prepare a sheet iron, welding and grinder.

According to the pre-made calculations cut out blanks of metal, weld or grind the sharp edges. Mounting the body performs, using screws and metal rivets. It is desirable for the body to be as airtight as possible, especially if you intend to carry loose cargo.

Variants of garden structures

The choice of basics for making self-propelled garden wheelbarrows today is quite extensive for the buyer. The most popular and practically significant wheelbarrow options are:

- Wooden wheelbarrows. An excellent natural material that even an inexperienced handyman can work with.

- Metal. Tubes of sufficient diameter for the frame, sheet iron - for the body. The only requirement is to pre-treat the surfaces and joints with a solution against corrosion.

- Plastic. Old PVC pipes are used for the frame, and plastic panels are suitable for forming the body. The material is relatively inexpensive, and PVC tubes with corners allow you to make an original folding cart.

- Combination models. The most common variant of constructions, made with their own hands. Metal pipes are used for the frame, and moisture treated wood acts as the basis for the body.

Today there is a huge selection of step-by-step instructions for novice craftsmen. Using these master classes, as well as having read the video tutorials, you can easily make a convenient, lightweight and maneuverable garden wheelbarrow for backyard work.